Steam

Technical Statement

Fundamentals of Steam

Steam is frequently used as a process medium because of its unique thermal properties. Because of these properties, steam is also inherently dangerous. It is therefore important to understand some of the facts about steam and how it is best handled with hose.

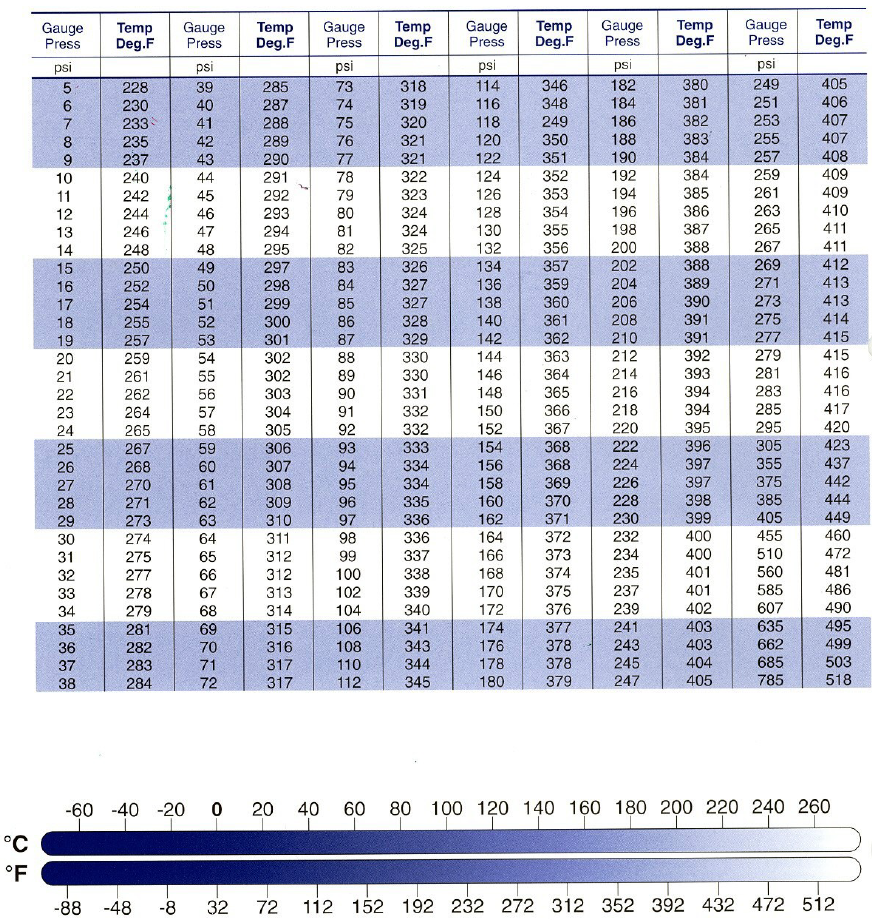

At atmospheric pressure (14.7 psi), water becomes steam, or boils, at 100°C.

When under increased pressure, boiling is delayed. At 200 psi, the boiling point becomes 198° C. At 600 psi, the temperature approaches 260°C.

If there is water and steam in the system, the steam is said to be in a wet saturated state.

As long as some liquid remains, the steam will stay at the boiling point. Any additional heat changes all the water into steam, at which point it becomes dry saturated steam. At this point, additional heat raises the temperature above the boiling point and the steam becomes superheated.

In an elastomer (rubber) hose application, dry saturated or superheated steam at or below the temperature rating of the hose is acceptable, though the hose will heat age over time.

Wet saturated steam poses a more sever problem to rubber and other elastomers because the inner core will absorb water. This will cause the tube to swell and deteriorate faster. In some cases the action of trapped water turning into steam can physically tear the Inner core creating a phenomenon called 'pop corning'. In any case, steam hose failures are usually caused by heat which either softens or hardens the hose material over time.

For this reason, smooth bore PTFE is the best choice for steam. PTFE hose can handle steam in any state up to its operating temperature of 260°C. Even steam and cold water cycles are easily handled with smooth bore hose and PTFE does not heat age.

Precautionary Notes

- For food, pharmaceutical or other high fluid velocity applications, it is recommended that conductive PTFE liner is used as insurance to prevent static discharge

- There is a risk of burns if skin contact is made with the metal braided hoses in steam use. Fibre braid options are available to offer some protection against this.

- At increased temperatures, the maximum working pressure of the hose should be de-rated accordingly. (E.g. at 190°C, Kongsberg recommend de-rating the pressure by 50% of the specification. It is strongly recommended that the end user carries out specific testing relevant to the intended application)

PTFE Smoothbore hose – Maximum working temperature: 260°C

"All results are believed to be based on valid laboratory or field test or experience; however, no guarantee is expressed or implied as to results that will be obtained by the user. It is recommended that the user test the anticipated combinations on his own laboratory before committing his product to any libelous application"