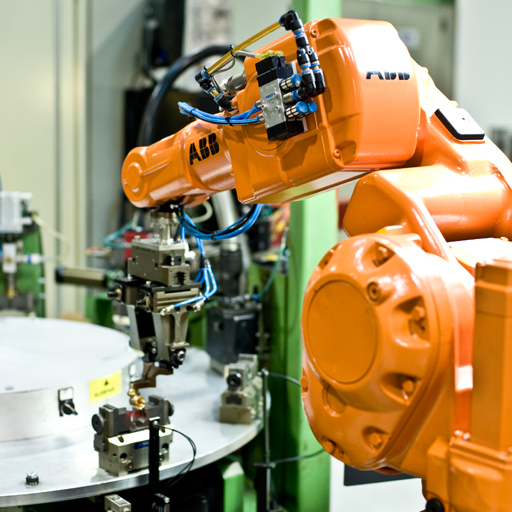

Industrial manufacturing

Features and benefits of PTFE

- Ability to handle a wide temperature variance: -60⁰C to +260⁰C

- Not affected by heat aging

- Low permeability rates making it suitable for the transportation of industrial gases

- Compatible with a very wide range of chemicals; one PTFE hose can convey multiple types of fluids and gases

- Not affected by Ozone or UV exposure

- Lowest co-efficient of friction of any solid material; results in better system efficiency due to lower pressure drops

- Superior flex fatigue life and non-flammable

- Unlimited shelf life

Given the wide and varied requirements of Industrial Manufacturing which include steam applications, high pressures, vibration, corrosive and harmful acids as well as high and cold temperature applications, only one hose type successfully meets the requirements of these various applications.

PTFE, with its wide operational temperature range of -60⁰C to +260⁰C, is ideally suited to the rigorous demands required by Industrial Manufacturing. In addition, the compatibility of PTFE with a wide range of chemicals and gases makes it the perfect “select one” hose to meet the majority of Industrial Manufacturing requirements with an exceptional field service life.