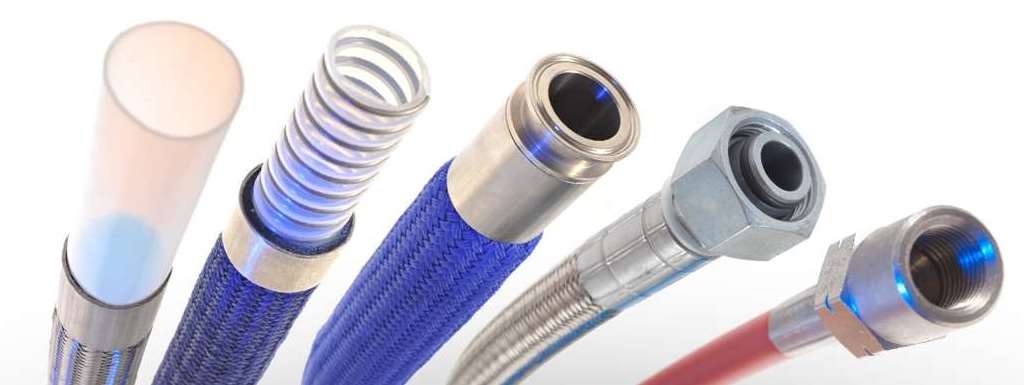

Air compressor discharge

Features and benefits

- Inert to air and air/oil mixtures compared to rubber hoses

- Extreme reliability, thus longer service life

- Compatible with high temperatures of compressed air when compared to rubber hoses

- More dependable; less maintenance and downtime

- Greater pressure ratings relative to comparable rubber hoses

- Greater safety and reliability; assured system dependability

- Unaffected by system vibration where rigid tubing often fails

- Less chance of leakage, thus greater system efficiency

- Less maintenance and downtime, thus lower operating cost

- Inherent flexibility compared to rigid tubing

- Easier to install and remove

- Lower pressure drop compared to rubber hose or rigid tubing

- Greater system efficiency

Portable and stationary air compressors of single and multi-stage design are used worldwide for a host of air-power requirements:

- Pneumatic construction tools

- Street and highway maintenance

- Quarrying and mining

- Petroleum research and development

- Pneumatic instrumentation systems in chemical, petrochemical, and refining industries

- Main air systems aboard ships

Critical among these are the compressed air discharge lines on single and multi-stage compressors. These lines must typically withstand air pressures from 7 bar (100 PSI) to about 275 bar (4,000 PSI) and temperatures from ambient to about 204° C (400°F).

In addition, such lines must be compatible with air/oil mixtures, not creating build ups of residues and at the same time be able to withstand inherent system vibration.

PTFE hoses are a perfect solution to convey compressed air from one stage to another, owing to minimal downtime and maintenance resulting in higher productivity; moreover, these hoses offer excellent dependability and versatility for total reliability and high performance.