Hot melts and adhesives

Features and benefits of PTFE

- Ability to handle a wide temperature variance: -60⁰C to +260⁰C

- Not affected by heat aging

- Compatible with a very wide range of chemicals

- Low permeability rates

- Not affected by Ozone or UV exposure

- Low co-efficient of friction—better system efficiency due to lower pressure drops

- Non flammable

- Superior flex fatigue life

- Low volumetric expansion

Hot melt is a process where a polymer-based glue or adhesive is applied in its molten state by using a heated hose and a glue gun. The process is widely used to glue various parts together in industrial segments like packaging, furniture, bookbinding, carton-making, labels, product assembly and in the automotive industry.

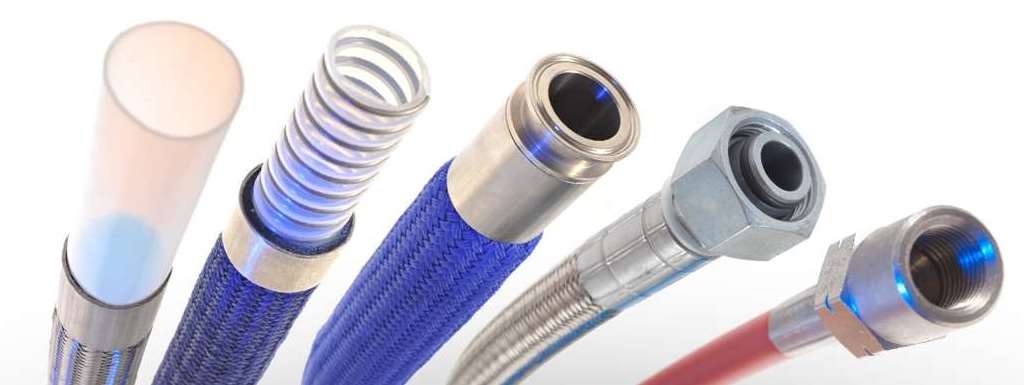

The heated hose is made of a PTFE liner with layers built around of stainless steel (or textile) braid, silicon tape, a heating element, several layers of fiberglass isolation followed by a protective sleeve.

Due to its unique properties, PTFE is the perfect solution for this application. PTFE can handle a wide temperature range of up to 260°C/ 500°F and has the lowest coefficient of friction of any solid known; these properties, along with non-stick properties, ensure continuous low pressure drops with no blockage during service.

PTFE liners are highly resistant against a very wide range of chemicals and adhesives, do not age and maintain superior flex fatigue resistance.