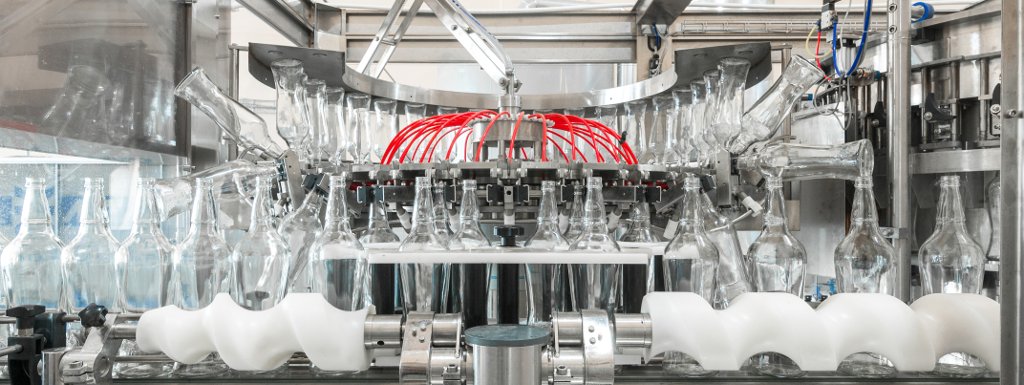

Cleaning & sterilising

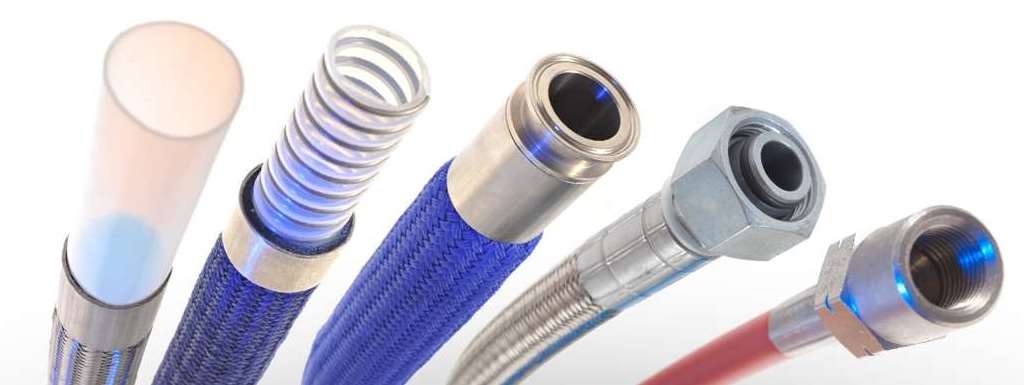

Features and benefits of PTFE

- Inert to almost all known chemicals

- Non sticky and easily cleaned due to the lowest coefficient of friction known; resists sorption of cleaning chemicals (COP, CIP)

- Permanently resistant to steam sterilization (SIP)

- PTFE has the ability to handle a wide temperature variance: -60⁰C to +260⁰C

- Non-reactive, there are no corrosion by-products extractables to contaminate processes; hence, no change in taste, odour or colour

- FDA approved and meets USP CLASS VI

- Available with FDA Approved Carbon to allow electrostatic release

- Good transparency

- Superior resistance to Flex Fatigue

- PTFE has longer Service Life

The (bio) pharmaceutical, cosmetic and medical industries utilize PTFE hoses for most processes and high-purity utility connections.The hoses are exposed to Processing, Sterilization, and Cleaning.

Sterilization and Cleaning usually stress the hoses more than the processes; most of the process have properties similar to water and operating temperatures are typically 25°C (4-40°C).

Sterilization is typically carried out with Steam at 125°C (121-135°C). Cleaning is carried out with mild acids, bases, disinfectants and rinsing with large amounts of High-Purity Water. Cleaning Temperatures are typically 62°C (25-90°C). Applications for High purity applications include Pure Steam and High Purity water such as Water for injection, USP Purified Water, Reverse Osmosis Water, Deionized Water, Clean Process Air, Clean Process Gasses and Chemical Reagents.

Unlike Silicon hoses, PTFE hoses are chemical inert, non-reactive and permanently resistant to cleaning and steam sterilization. The equipment stays cleaner during operations and the system cleaning is faster due to PTFE surfaces being smooth and nonwetting; moreover, these surfaces resist biofilm buildup and there are no transitory chemical interactions with PTFE during operations or startup.