UltiFlex® - Used globally in Pharmaceutical and Food & Beverage Industries

Pharmaceutical

High purity and sanitation are key focuses for the Pharmaceutical industry which develops, produces and markets pharmaceutical drugs. The finished products are usually chemically synthesized with organic solvents and are used for medications and cures in human beings and animals.

The unique properties of PTFE creates many benefits for the companies operating in the Pharmaceutical industrie. Unlike Stainless Steel, PTFE doesn’t require passivation or Electro-Polishing. Unlike Glass, PTFE isn’t subject to cracking or crazing and rarely requires repair. Furthermore, unlike Silicon hoses, PTFE is chemically inert, non-reactive and permanently resistant to steam sterilisation (SIP) and in-place cleaning (CIP).

Food & Bevarage

PTFE as a flexible hose material is by far the most widely specified material for Food & Beverage processing applications of all types, including but not limited to production of dairy products, powders, syrups and sauces, prepared meats, wine, beer & spirits. PTFE is chemically inert; the hose will not affect the product conveyed in any way at the wide-ranging operating temperature of -60⁰C to +260⁰C. It will not impart any colour, flavour or odour and PTFE will not absorb or remove ingredients, not even moisture. PTFE has an ultra-low coefficient of friction this means that it is non-stick, will not build up residues, is fast and easy to clean and above all, hygienic.

Ultiflex

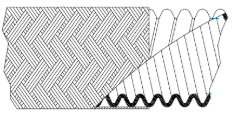

UltiFlex®, which is an externally convoluted, inner smoothbore PTFE hose construction is a hybrid of both traditional Convoluted & Smoothbore hose types. You gain the advantages and benefits of flexibility, superior flow and cleanability all in one hose, Flexibility & Flow make UltiFlex® the ultimate application problem solver and has earned compliance and approval with FDA, EU-2011 Food, USP Class VI, Anti-static (AS) & EN;16643 (Partial).

The highlight of UltiFlex® is the patented hose manufacturing method by Kongsberg Automotive. The PTFE hose liner design which comprises of castellation sections gives the hose its flexibility but also supports the tube against kinking and gives full vacuum and pressure ratings. The outstanding characteristics of UltiFlex® make it one of the most versatile PTFE Flexible hose products on the market.

|

|

|

||

| Hybrid Ultiflex PTFE hose | Traditional Convoluted PTFE Hose | Traditional Smoothbore PTFE Hose |

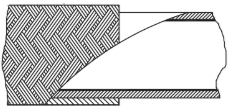

UltiFlex® process PTFE hoses are available from Kongsberg Automotive as bulk hose for self-assembly customers or as complete hose assemblies with Flared / Tafted / Lined end fittings to improve cleanliness, remove or reduce bug traps and improve the ability to clean in place (CIP) & steam in place (SIP). The PTFE liner, available in Virgin (Natural) or Anti-static (Carbon) is extended through the end fitting, then flared out against the sealing face of the end fitting. Therefore, the media passing through the hose contacts only the chemically resistant PTFE liner ‘wetted parts’.

Should you have any further questions or wish to learn more about the UltiFlex® product range please do not hesitate to contact the dedicated Process Hose Global Sales Manager